Cutting-Edge Self-Cleaning Filters Transform Industrial Water Management for Paper and Textile Sectors

Publication time:2025-06-28

Introduction

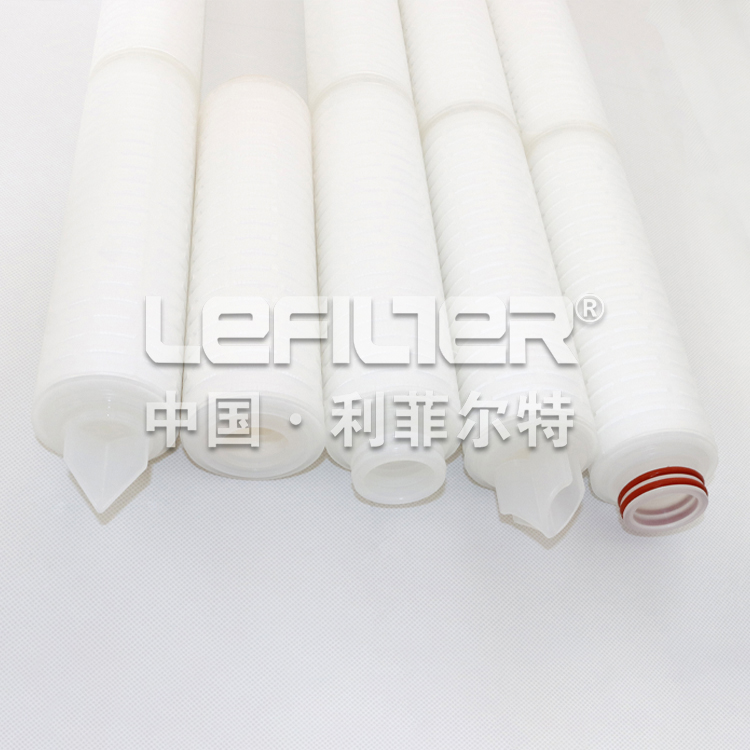

For sixteen years, LEFILTER has stood at the vanguard of filtration technology from our manufacturing hub in Xinxiang City, Henan Province. We've built our reputation by delivering premium-quality alternatives to overpriced branded filters from industry giants like PALL and Parker. Today, our latest generation of intelligent self-cleaning filtration systems is setting new benchmarks in industrial water treatment, particularly for paper mills and textile plants grappling with challenging process water contaminants.

The New Standard in Industrial Filtration Economics

In an era where manufacturing efficiency and sustainability intersect, LEFILTER's direct-from-factory production model disrupts traditional supply chains by offering:

1. Unmatched value: 40-60% cost advantage over comparable European/American systems

2. Lightning-fast delivery: Standard units ship within 10 working days

3. Application-specific engineering: Custom solutions developed in 5 business days

4. Zero-compromise quality: Rigorous testing protocols matching EN 1822 standards

"Our manufacturing agility allows us to implement customer feedback into product improvements within weeks, not years," explains LEFILTER's Chief Technology Officer. "This responsiveness gives our clients a competitive edge in their markets."

Next-Generation Self-Cleaning Mechanisms

LEFILTER's proprietary filtration technology addresses the most persistent challenges in industrial water treatment through:

1. Adaptive Cleaning Systems

Vortex-assisted backwashing for heavy fiber loads

Ultrasonic enhancement for stubborn deposits

AI-driven cycle optimization learning from operational patterns

Fail-safe redundancy ensuring continuous operation

2. Engineered for Extreme Conditions

Corrosion-resistant alloys: Super duplex stainless steel options

High-temperature variants: Stable performance up to 120°C

Explosion-proof configurations: ATEX-compliant designs available

Modular scalability: From 5 m³/h pilot systems to 5,000 m³/h industrial plants

Paper Industry Breakthroughs: Revolutionizing Pulp Water Management

1. Modern paper manufacturing consumes 10-50 m³ of water per ton of product, with traditional filters struggling against:

Micro-fine cellulose fibers

Sticky sizing agents

Abrasive mineral fillers

Temperature fluctuations

2. LEFILTER's LFP series delivers transformative results:

99.7% fiber capture efficiency at 50μm precision

Self-adjusting cleaning cycles responding to contaminant loading

75% reduction in backwash water consumption

Integrated water quality monitoring with cloud connectivity

3. A recent deployment at a tissue paper manufacturer achieved:

18% increase in production uptime

¥1.2 million annual savings in water-related costs

30% reduction in energy use versus conventional systems

Zero filter replacements in 24 months of operation

Textile Sector Solutions: Mastering Complex Dyehouse Effluents

1. The textile industry's water challenges multiply with:

Colloidal dye particles

Synthetic fiber microplastics

Alkaline cleaning solutions

Variable flow conditions

2. Our LFT series introduces groundbreaking capabilities:

pH-resistant membranes (stable from 2-12 pH)

Microplastic interception down to 25μm

Color removal efficiency exceeding 85%

Compact vertical designs for space-constrained facilities

3. Implementation data from a knit fabric dyeing plant shows:

94% decrease in effluent violations

65% lower chemical consumption for pH adjustment

40% faster processing from consistent water quality

15-month payback period on capital investment

The LEFILTER Difference: Beyond the Product

1. Rapid Prototyping Service: Test customized solutions in your facility within 15 days

2. Lifecycle Cost Modeling: Transparent 10-year operational cost projections

3. Global Compliance Support: Documentation for CE, ASME, and GB standards

4. On-Demand Upgrades: Field-retrofittable technology enhancements

5. Circular Economy Programs: Filter element recycling initiatives

Industry Recognition and Future Vision

1. Recent validation includes:

2024 Industrial Water Innovation Award for textile applications

Case study publication in Water Treatment Technology journal

Strategic partnerships with three global paper conglomerates

2. Looking ahead, LEFILTER is developing:

Bio-inspired membrane surfaces mimicking lotus leaf structures

Piezoelectric cleaning systems reducing energy needs

Nanocomposite materials combining graphene enhancements

Mobile treatment units for decentralized production sites

Sustainable Water Stewardship

Every LEFILTER installation contributes to:

1. Water footprint reduction: Saving 2-5 million liters annually per system

2. Energy conservation: 35-60% lower carbon emissions

3. Waste minimization: 90% less filter media sent to landfills

4. Chemical reduction: Decreased treatment additive requirements

Making the Switch: Seamless Transition Support

We facilitate smooth adoption through:

1. Process water audits: Identifying optimization opportunities

2. Retrofit engineering: Adapting existing infrastructure

3. Operator training programs: Ensuring peak performance

4. Performance guarantees: Backed by insured warranties

Conclusion: The Future of Industrial Filtration is Here

As water scarcity concerns intensify and environmental regulations tighten, LEFILTER's intelligent self-cleaning filters provide paper and textile manufacturers with an unprecedented combination of performance, affordability, and sustainability. Our vertically integrated manufacturing ensures consistent quality control while maintaining the cost advantages that have made us the preferred alternative to premium brands.

To explore how our solutions can transform your water management approach, contact our engineering team today for a customized proposal.