Security Filter Applications Across Industries: Guarding Water Quality with Precision

Publication time:2025-06-30

Security filter systems serve as the first line of defense in water and fluid treatment infrastructures, intercepting impurities before they can reach sensitive downstream equipment such as pumps, valves, reverse osmosis membranes, or precision instruments. From pharmaceuticals and petrochemicals to semiconductors, HVAC systems, and municipal waterworks, Industrial filter units enable consistent performance, extend system life, and reduce operational risk.

In pharmaceutical and biotech production, Water security filter solutions ensure high-purity water required for drug formulation and sterile environments, shielding systems from fine particulates and microbes. In petrochemical and refinery operations, Industrial water filter systems are critical for protecting process equipment from scaling and erosion due to contaminated cooling water or utility streams, while also maintaining catalytic efficiency.

Meanwhile, Safety filters for water are indispensable in food and beverage processing, preventing contamination in mixers, fillers, and pasteurizers, while supporting HACCP and FDA compliance, and maintaining taste and shelf-life standards.

Specialized Industrial and Utility Applications

Security filter technology plays a vital role in precision manufacturing environments, especially in electronics and semiconductor industries, where waterborne particles can lead to critical surface defects or conductivity failures. These filters uphold ultra-clean conditions essential for advanced chip production.

In large municipal water treatment plants, Industrial filter systems are positioned between coarse filtration and final disinfection steps like UV sterilization or chlorination, acting as a polishing stage to remove residual debris that could reduce disinfection effectiveness or cause equipment fouling.

Automotive and metal processing sectors also rely heavily on Water security filter devices to prevent spray nozzle blockages, reduce wear in cooling systems, and support water recycling loops aligned with zero-liquid discharge initiatives.

Within HVAC infrastructure for airports, hospitals, and commercial centers, Industrial water filter units help maintain heat exchanger efficiency and reduce microbial buildup in chilled water systems, ensuring energy efficiency and continuous operation.

Expanding Into Emerging and Residential Fields

Beyond conventional sectors, Safety filters for water are being adopted in emerging applications such as aquaculture, precision agriculture, eco-resorts, and luxury residential systems. Here, they ensure water quality for fish health, crop yield, guest comfort, and appliance longevity—demonstrating the adaptability of Security filter systems even in non-industrial contexts.

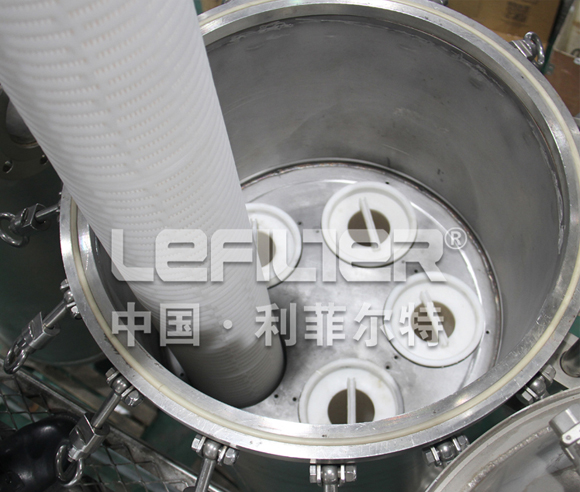

Their broad applicability is underpinned by flexible design choices: Industrial filter units are available in a variety of materials like carbon steel, stainless steel (304/316L), FRP, or even titanium, and support diverse filtration media—wedge wire screens, pleated cartridges, sintered elements—depending on operational needs.

These filters can be customized based on flow rate, operating temperature, chemical compatibility, and pressure ratings, making them a highly configurable component for industrial designers and procurement engineers aiming for both protection and process optimization.

Smart Features and Environmental Impact

Modern Security filter solutions go beyond basic filtration, integrating advanced features like differential pressure gauges, auto-drain valves, or even self-cleaning mechanisms that help reduce manual labor, enable predictive maintenance, and avoid system shutdowns due to unexpected clogging.

Industrial filter designs are increasingly optimized for low maintenance and longer service cycles, ensuring they meet the needs of continuous-process industries. These innovations not only protect infrastructure but also align with the demands of Industry 4.0 and smart facility operations.

Furthermore, Water security filter units offer a minimal environmental footprint. Unlike chemical-based pretreatment, mechanical filtration introduces no harmful by-products or secondary pollution. These systems help industries meet ISO 14001 and LEED requirements by reducing waste, eliminating chemical handling, and lowering water discharge volume, all while preserving valuable resources.

Long-Term Value and Future Outlook

As industries face rising environmental regulations, stricter product quality demands, and growing water scarcity, the strategic deployment of Industrial water filter systems—especially security filters—will become increasingly vital to sustainable and resilient operations.

Safety filters for water provide not only cost-effective protection but also bring long-term value by reducing unscheduled maintenance, improving water system performance, enhancing regulatory compliance, and preserving environmental credentials.

Whether in traditional manufacturing or forward-looking smart water management platforms, Security filter technology will continue to serve as a cornerstone of quality assurance, operational efficiency, and responsible water stewardship—making it a wise investment for industries seeking dependable and future-ready filtration solutions.