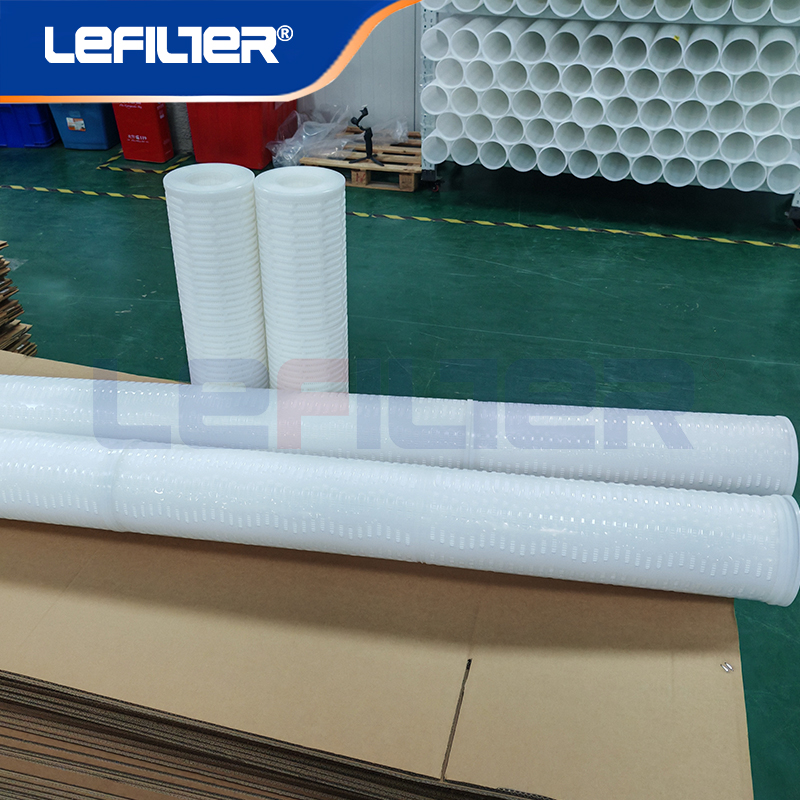

Innovative Design and Structural Features

1.Surface Expansion Through Pleated Design

The Pleated Cartridge represents a significant advancement in filtration technology through its unique folded membrane structure. Unlike conventional cylindrical filters, the Pleated Membrane Filter configuration increases the effective filtration surface area by up to 400% within the same housing dimensions. This engineering breakthrough allows for substantially higher particulate loading capacity while maintaining compact system footprints.

2.Multi-Layer Construction for Enhanced Performance

Modern Pleated Water Filter Cartridges incorporate sophisticated layered architectures that combine:

• A protective outer layer for coarse particulate removal

• A precision middle layer for fine filtration

• A structural support core ensuring dimensional stability

This tiered approach enables the Pleated Membrane Filter Cartridge to achieve progressive filtration, effectively extending service intervals and reducing total cost of ownership.

Material Selection for Specific Applications

Manufacturers utilize various advanced materials in Pleated Cartridge production:

• Polypropylene (PP): The most common choice for general water filtration, offering excellent chemical resistance

• Nylon: Provides superior temperature tolerance for hot process fluids

• Glass Fiber: Used in high-efficiency applications requiring absolute filtration

• PTFE Membranes: Incorporated in Pleated Membrane Filters for extreme chemical resistance

Unparalleled Filtration Performance and Efficiency

1.Exceptional Contaminant Removal Capabilities

The Pleated Water Filter Cartridge demonstrates remarkable filtration efficiency across multiple particle sizes:

• 90-100 micron: Effective for sediment and large particulate removal

• 5-25 micron: Ideal for general industrial water treatment

• 1-5 micron: Suitable for high-purity applications

• Sub-micron: Achievable with specialized Pleated Membrane Filter Cartridge configurations

Independent testing confirms that properly specified Pleated Cartridges can achieve >99.9% particulate removal at rated micron levels.

2.Optimized Flow Dynamics and Pressure Characteristics

Through computational fluid dynamics (CFD) modeling, modern Pleated Membrane Filters achieve:

• 30-50% lower initial pressure drop compared to conventional depth filters

• More stable differential pressure throughout the service life

• Higher sustained flow rates (typically 5-15 GPM per 10" element)

These characteristics make the Pleated Water Filter Cartridge particularly valuable in high-flow applications where energy efficiency is paramount.

Critical Applications Across Industries

1.Water Treatment Solutions

Municipal Drinking Water Systems

The Pleated Cartridge has become indispensable in modern water treatment plants for:

• Pretreatment filtration prior to reverse osmosis systems

• Final polishing of potable water supplies

• Removal of turbidity and suspended solids

2.Industrial Process Water

Manufacturing facilities utilize Pleated Membrane Filter Cartridges for:

• Cooling tower water filtration

• Boiler feed water treatment

• Process water clarification

3.Seawater Desalination

As pretreatment barriers, Pleated Water Filter Cartridges effectively:

• Remove marine organisms and algae

• Reduce sediment loading on downstream equipment

• Maintain consistent flow rates despite challenging feed water conditions

4.Food and Beverage Industry Applications

Beverage Production

From bottled water to alcoholic beverages, Pleated Membrane Filters ensure:

• Consistent product clarity

• Yeast and processing aid removal

• Compliance with food safety standards

5.Dairy Processing

The Pleated Cartridge is particularly effective for:

• Milk and whey filtration

• Removal of casein fines

• Bacteria reduction in process streams

6.Liquid Food Production

Food manufacturers rely on Pleated Water Filter Cartridges for:

• Edible oil filtration

• Syrup and sweetener clarification

• Process water purification

Conclusion

The Pleated Water Filter Cartridge represents the current pinnacle of filtration technology, combining superior engineering with practical operational benefits. As industries continue demanding higher efficiency and lower lifecycle costs, the Pleated Membrane Filter Cartridge is poised to become even more prevalent across water treatment and food processing applications.

For operations requiring reliable, high-performance filtration solutions, the Pleated Cartridge offers an optimal balance of:

• Exceptional contaminant removal

• Energy-efficient operation

• Long service intervals

• Cost-effective maintenance

FAQ:

Q:How does a Pleated Cartridge Filter differ from a Membrane Filter Cartridge?

A:While a Membrane Filter Cartridgerelies on a fine porous membrane for microfiltration, a Pleated Cartridge Filteruses pleated media for depth filtration, offering higher dirt-holding capacity and better flow rates in high-particulate applications.

High Flow Water Filter Element