Introduction

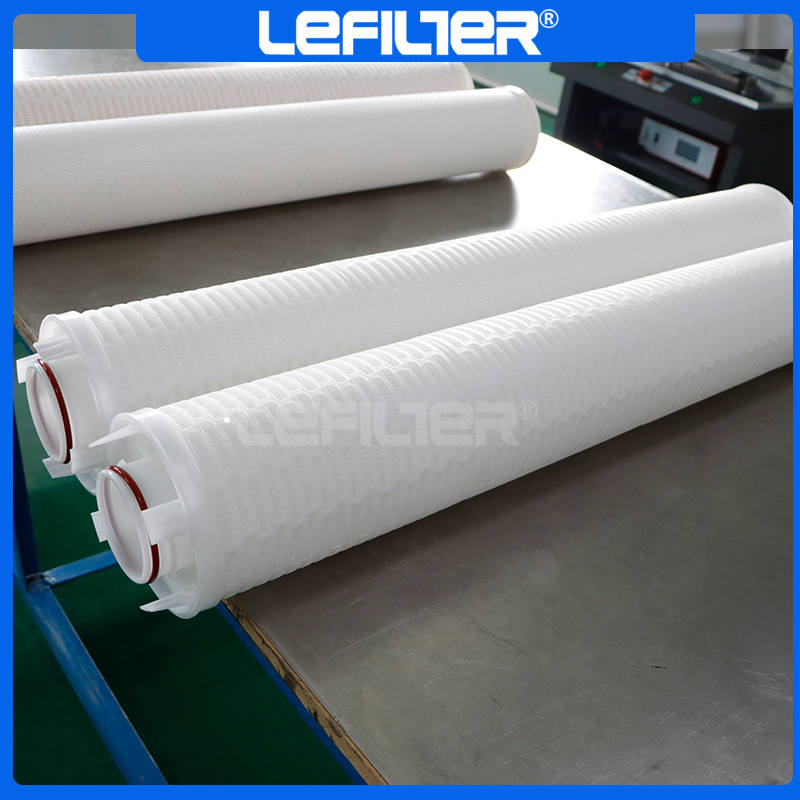

As a trusted manufacturer with 16 years of expertise in filtration solutions, we specialize in producing high-quality PP melt-blown filter cartridges that serve as direct, cost-effective alternatives to premium brands like Pall and Hydac. Our filters deliver exceptional filtration efficiency, high flow rates, and reliable chemical resistance—all at a fraction of the cost of branded options.

In industries where chemical liquid purity is non-negotiable—such as electroplating, paint manufacturing, solvent processing, and detergent production—even minor contaminants can lead to product defects, equipment damage, and costly downtime. Our PP melt-blown cartridges are engineered to remove impurities efficiently, ensuring process stability and superior end-product quality.

In Chemical Filtration

1. Advanced Depth Filtration Technology

PP melt-blown cartridges utilize a gradient-density structure, meaning the pore size decreases from the outer layers to the inner core. This design allows:

Progressive particle capture – Larger contaminants are trapped first, while finer particles are retained deeper in the media.

Higher dirt-holding capacity – Reduces clogging and extends service life compared to surface filters.

Lower pressure drop – Maintains optimal flow rates even with high-viscosity fluids like resins, adhesives, and electroplating baths.

2. Superior Chemical Resistance

Polypropylene (PP) is inherently resistant to:

Acids & alkalis (e.g., sulfuric acid, caustic soda)

Organic solvents (e.g., acetone, toluene, ethanol)

Oxidizing agents (e.g., hydrogen peroxide)

This makes our filters ideal for aggressive chemical environments where other materials (e.g., nylon or cellulose) would degrade.

3. High Flow Rates for Industrial Efficiency

Many chemical processes require fast, continuous filtration to maintain productivity. Our cartridges feature:

Optimized fiber distribution – Ensures consistent flow with minimal energy loss.

Large filtration surface area – Maximizes throughput for applications like solvent recycling or bulk chemical processing.

4. Cost Savings Without Compromise

Branded filters (e.g., Pall, Hydac) often come with a premium price tag, but our direct-to-customer manufacturing allows us to offer:

30–50% lower cost with equal or better performance.

Faster turnaround times (samples in 3 days, bulk orders in 5–10 days).

Customizable options (sizes: 10"–40"; micron ratings: 1–100μm; end caps: 222/226, threaded, flanged).

Applications

✔ Electroplating & Metal Surface Treatment

Removes particles (metal oxides, carbon residues) from nickel, copper, and chromium plating baths.

Prevents defects (pitting, roughness) in finished coatings.

Extends bath life by reducing contamination buildup.

✔ Paints, Inks & Coatings

Filters out agglomerated pigments, gels, and undissolved solids.

Ensures smooth application in spray systems, rollers, or dip tanks.

Reduces nozzle clogging in automotive and industrial coating lines.

✔ Solvent Purification & Chemical Processing

Cleans acetone, IPA, and specialty solvents for pharmaceuticals and electronics.

Protects sensitive equipment (e.g., chromatography systems, reactors).

✔ Detergents & Cleaning Solutions

Eliminates undissolved salts, silica, and processing byproducts.

Improves clarity and stability in liquid soaps and industrial cleaners.

Why Choose Us?

✅ 16 Years of OEM/ODM Experience – Proven quality for global clients.

✅ Strict QC Standards – Each batch tested for bubble point, flow rate, and particle retention.

✅ Fast & Flexible Service – Rush orders, custom designs, and technical support.

Conclusion

For chemical manufacturers seeking high-performance filtration without the premium cost, our PP melt-blown cartridges offer the perfect balance of quality, affordability, and speed. By switching to our filters, you gain:

✔ Longer filter life with superior dirt-holding capacity.

✔ Stable production and fewer downtime incidents.

✔ Significant cost savings—redirect your budget to growth, not overpriced consumables!

Contact us today for samples or a consultation—let’s optimize your filtration process together!

Product Range

Engineered for industrial excellence, TitanFlow Pro redefines filtration performance with its revolutionary Vortex-Tech media that delivers 99.99% particle capture at 1 micron while maintaining industry-leading flow rates of 600 GPM.

Key Innovations:

✔ Adaptive Pleat Technology™ – Auto-adjusts to load conditions for consistent performance

✔ Carbon-Neutral Construction – 100% recyclable materials with 70% lower environmental impact

✔ Instant-Connect System – Tool-free replacement in under 60 seconds

✔ SmartChip Monitoring – Tracks filter life, pressure drop, and contamination levels in real-time